Structural and functional composite materials

Research ClustersHigh Temperature Processes (HTP) Research GroupSmart Machining and Green EngineeringApplied Mechanics, Vibration and AcousticsApplied Machine Learning (AML)Industrial Engineering and Management (IEM)Applied Thermal EngineeringRenewable Energy LabEnergy and Environmental Simulation LabInternational ResearchStructural and functional composite materials

Structural and functional composite materials

Principal Investigator:

• Dr. Mohammad Ahsan Habib;

Professor & Head of the Department, Department of Mechanical and Production Engineering, Islamic University of Technology

Co-Investigator:

• Dr. Mohammad Nasim

Assistant Professor, Department of Mechanical and Production Engineering, Islamic University of Technology

•Dr. Abu Shaid Sujon

Assistant Professor, Department of Mechanical and Production Engineering, Islamic University of Technology

• Md. Hasibur Rahman Hamim

Junior Lecturer, Department of Mechanical and Production Engineering, Islamic University of Technology

Undergraduate researchers:

• Sazidur Rahman Chowdhury (ME’20)

• Ahsanul Amin (ME’20)

• Md Abraar Hossain (ME’20)

• Tasfia Binte Afsar(ME’20)

Research

The world is shifting from monolithic materials to composite materials due to its many useful properties. Composites are materials that are constructed from two or more materials. Our research group aims to develop and characterize composite materials for use in structural and functional applications by leveraging our expertise in mechanical engineering and material science.

Research themes

Sustainable fibers-reinforced composites

Principal investigator: Prof. Dr. Mohammad Ahsan Habib

Associate investigators: Dr. Abu Shaid Sujon; Md. Hasibur Rahman Hamim

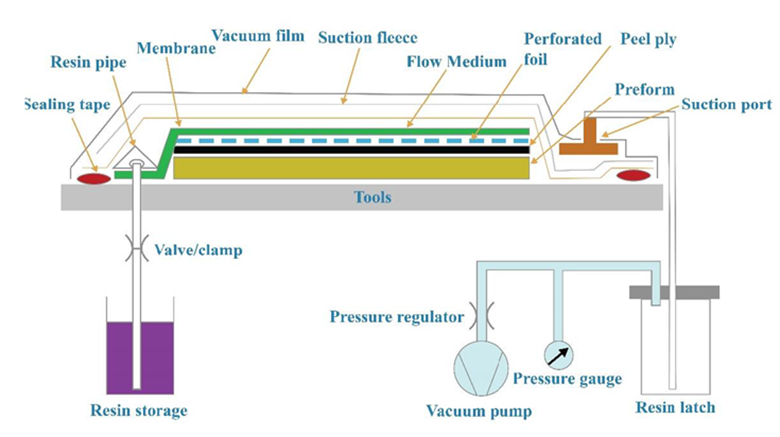

Incorporating the diverse properties of cellulosic fibers, commonly known as natural fibers, to develop composite materials have been an active area of research for the past half – century. With the aim to produce sustainable materials for applications, we employ fabrication techniques such as vacuum resin-infusion, hand layup vacuum pressing to produce composite materials reinforced with untreated, or chemically modified, natural fibers . We also aim to provide an in-depth analysis of the mechanical behavior of the developed composite materials using state-of-the-art CO2 laser cutting techniques to develop the specimens, and characterization techniques such as tensile, flexural, impact, vibration and moisture absorption tests, along with Scanning Electron Microscopy (SEM) imaging. Our area of application for our developed composites includes, but not limited to, automotive, infrastructure and biomedical engineering. We are also investigating on the effect of nanofillers (such as graphene) on the mechanical and electrical properties of the sustainable composites.

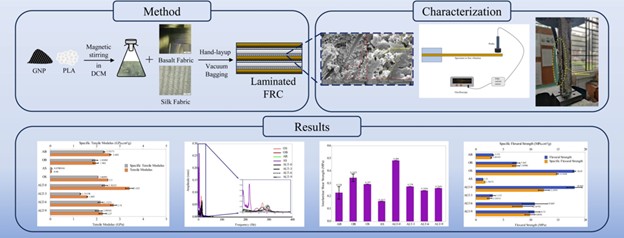

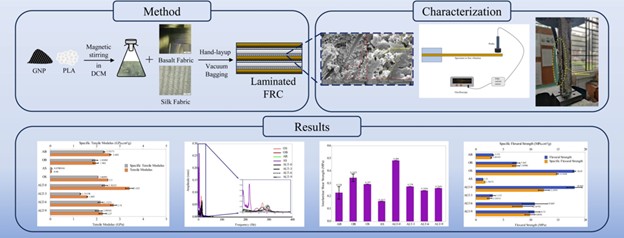

Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence

Biocompatible basalt-silk fiber/PLA composites were developed using five stacking sequences and graphene nanoplatelet (GNP) reinforcement. The ALT configuration exhibited the best mechanical properties, with a tensile strength of 136.54 MPa and impact energy of 36.84 kJ/m². SEM analysis revealed delamination as the primary failure mode. The addition of 6 wt.% GNP enhanced damping but failed to achieve conductivity. These sustainable composites hold promise for multifunctional applications with reduced environmental impact.

Fig 1: Graphical abstract from “Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence” (Hamim HR et al, Composites Part C: Open Access, 2025)

Fig 1: Graphical abstract from “Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence” (Hamim HR et al, Composites Part C: Open Access, 2025)

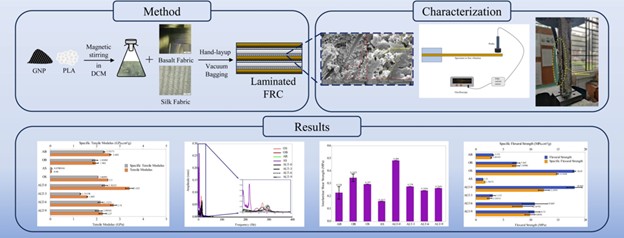

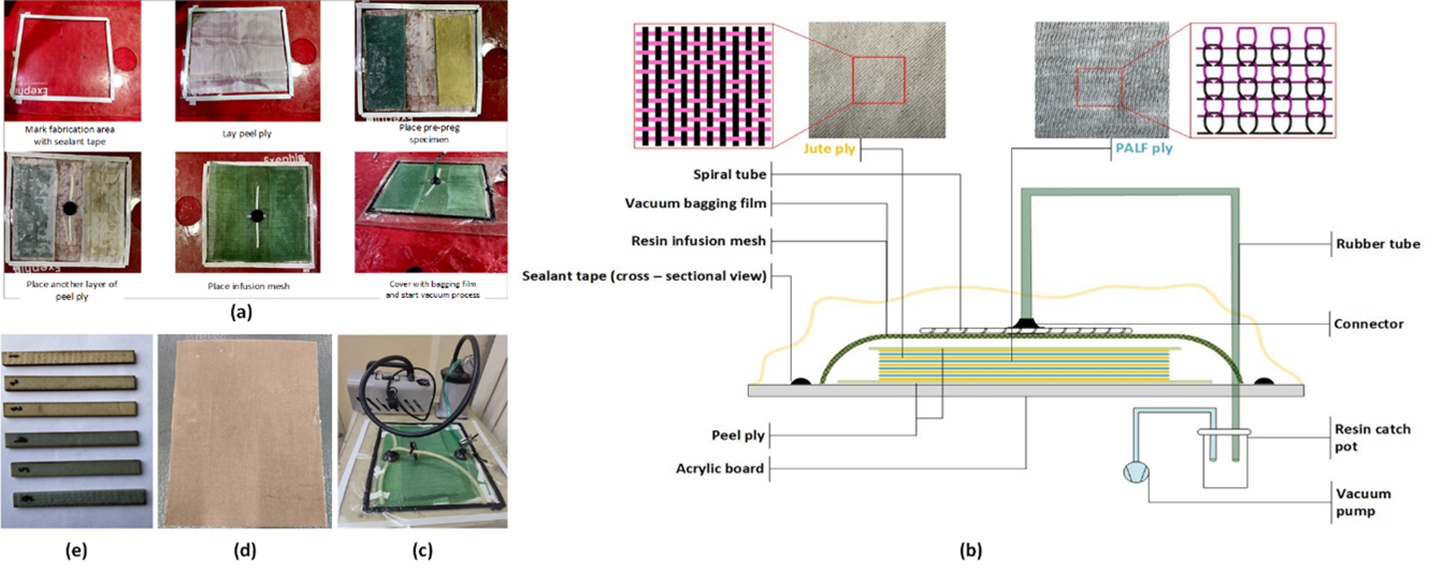

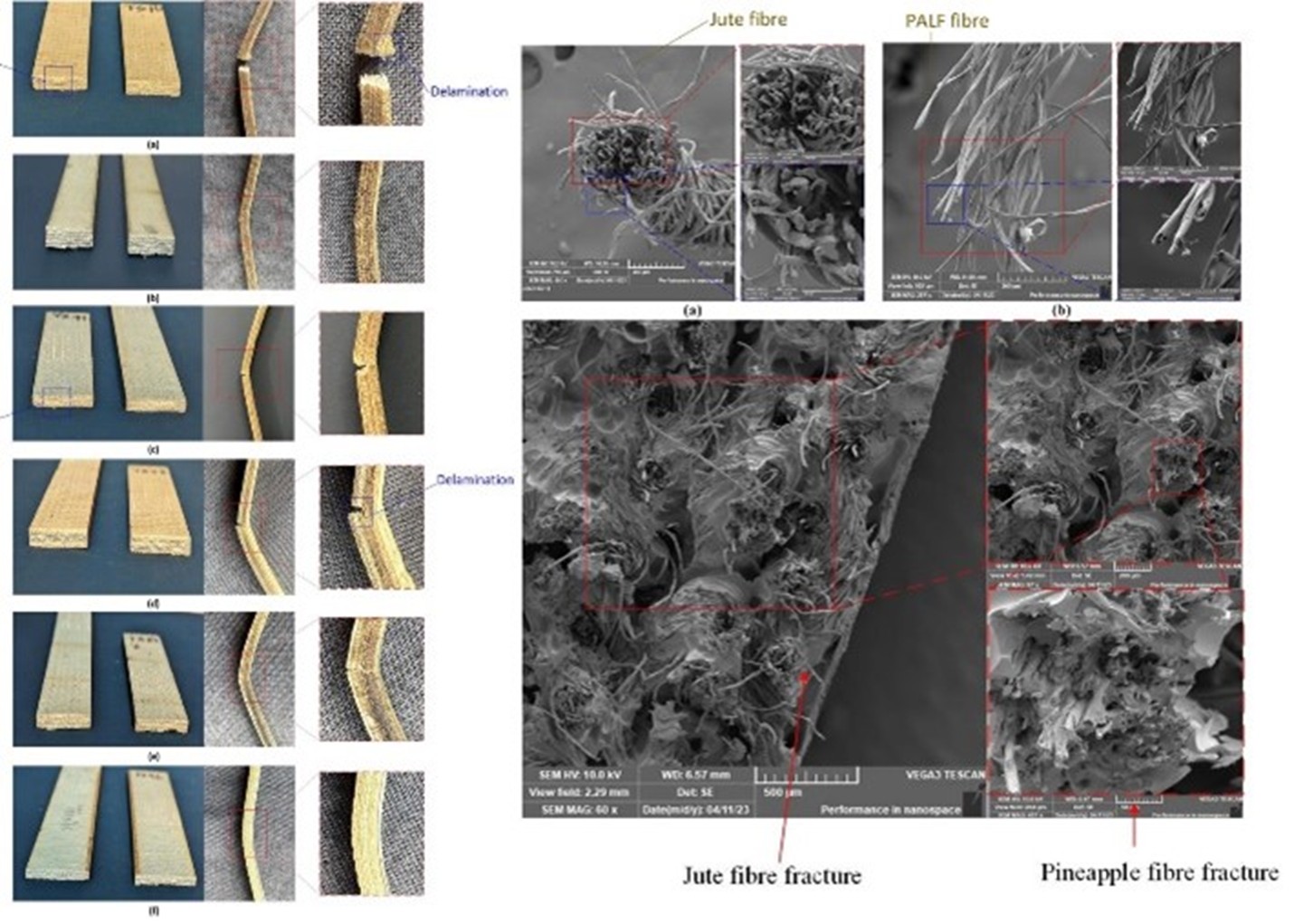

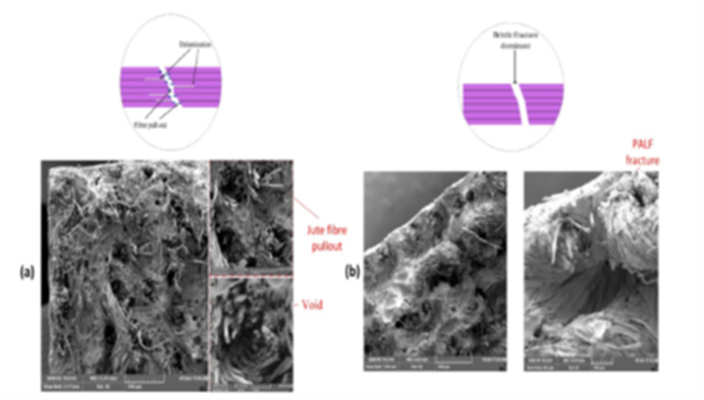

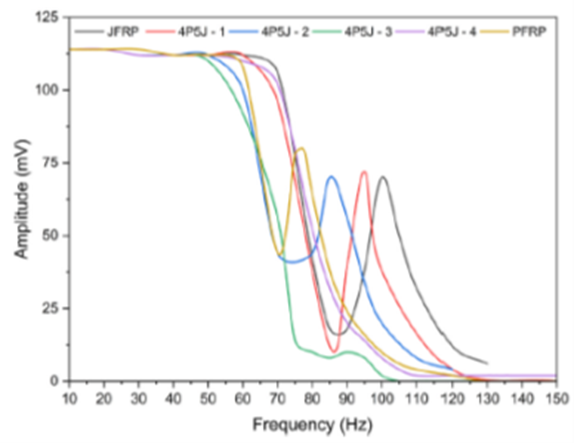

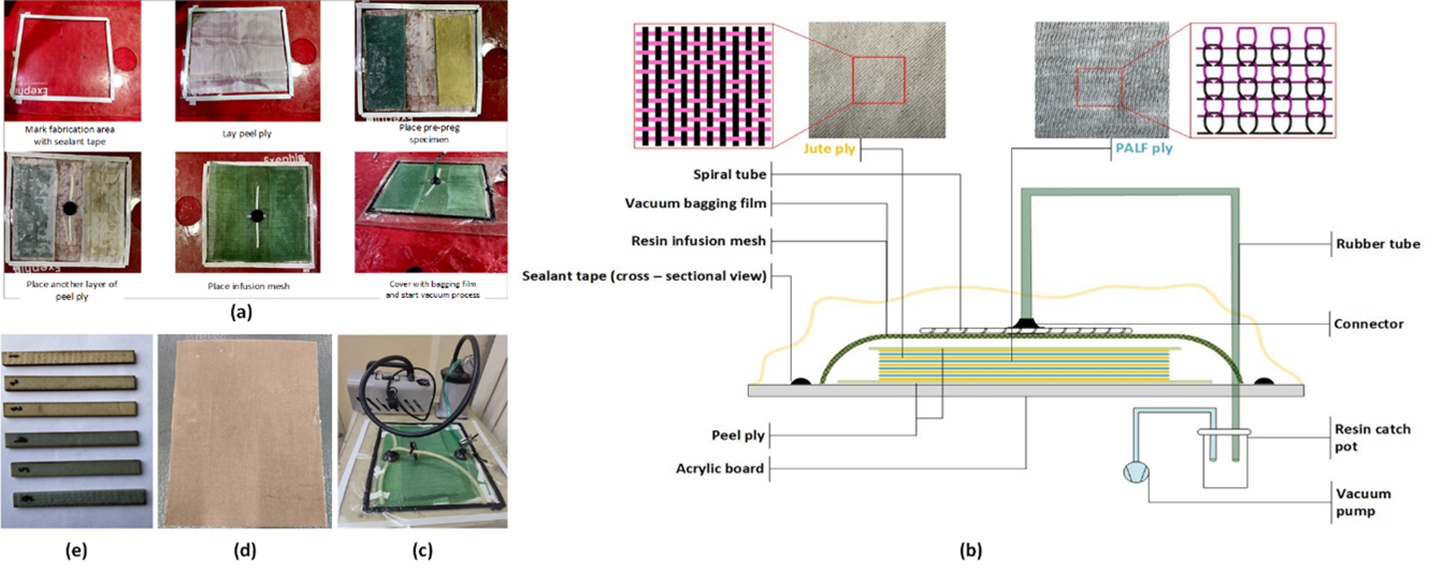

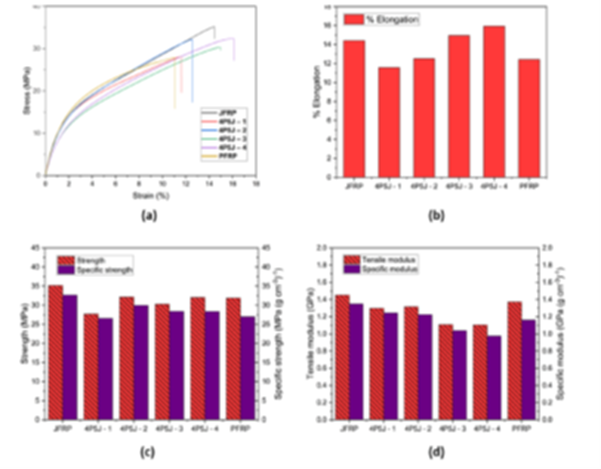

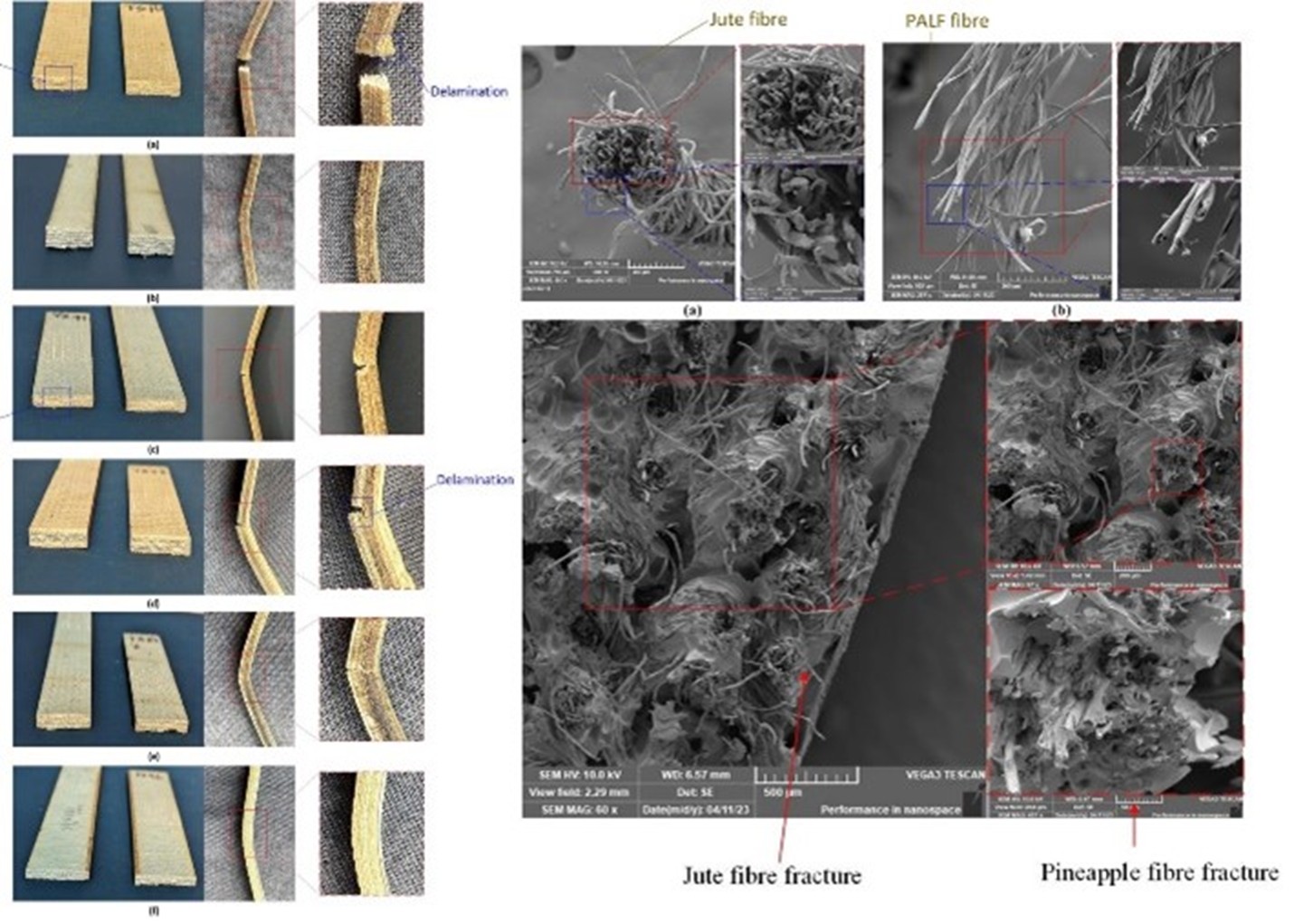

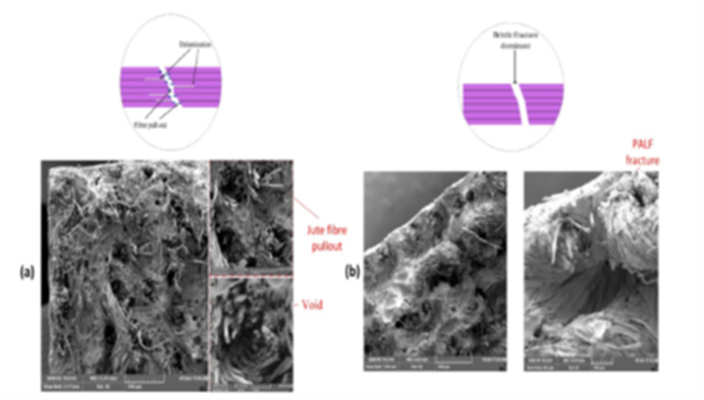

A comprehensive study on the effect of hybridization and stacking sequence in fabricating cotton-blended jute and pineapple leaf fibre biocomposites

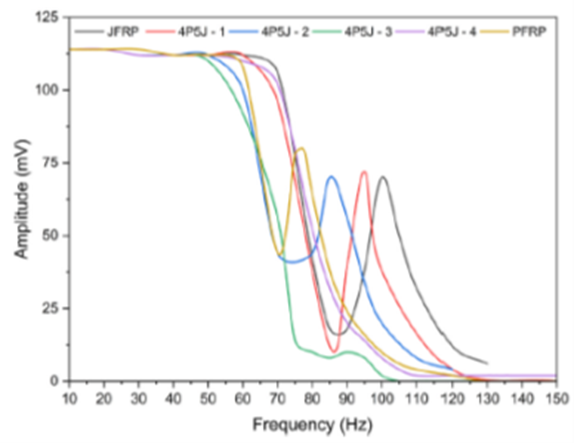

Hybridizing biocomposites by combining discarded cotton-blended pineapple leaf fiber (PALF) and jute fiber fabrics enhances recyclability and sustainability. Four hybrid and two unhybridized composites were analyzed for mechanical, moisture absorption, and vibration properties. JFRP composites showed the highest tensile strength (35.16 MPa), while hybrid composites reached 32.16 MPa. The 4P5J-2 stacking sequence exhibited the highest tensile modulus (1.315 GPa), and a jute-dominant hybrid had the greatest elongation (15.94%). The 4P5J-1 hybrid achieved a flexural strength (44.36 MPa) comparable to JFRP (44.91 MPa) with a 78.57% flexural modulus increase over PFRP. Moisture absorption decreased with hybridization, and PALF plies on the outer layers improved damping. These findings highlight hybridization and stacking sequence as key factors in composite performance, promoting the use of textile waste for sustainable automotive applications.

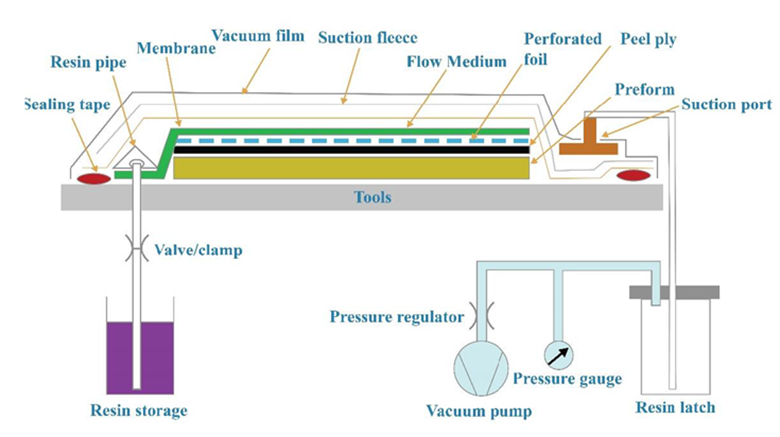

Fig 2: Fabrication and analysis of cellulose fiber-based composites using vacuum bagging. Image taken from (Baigh & Nanzeeba et al, Heliyon, 2023)

Fig 2: Fabrication and analysis of cellulose fiber-based composites using vacuum bagging. Image taken from (Baigh & Nanzeeba et al, Heliyon, 2023)

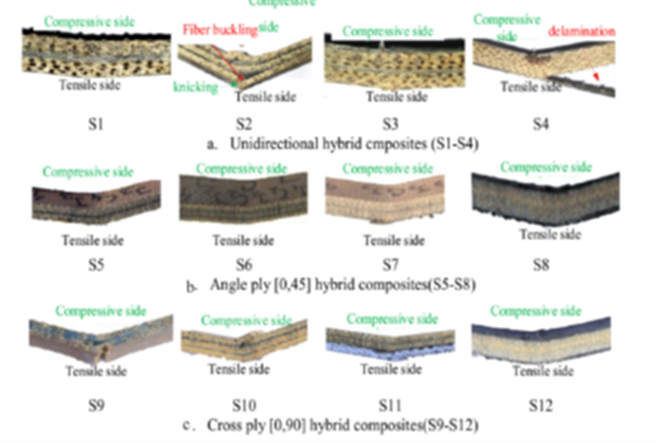

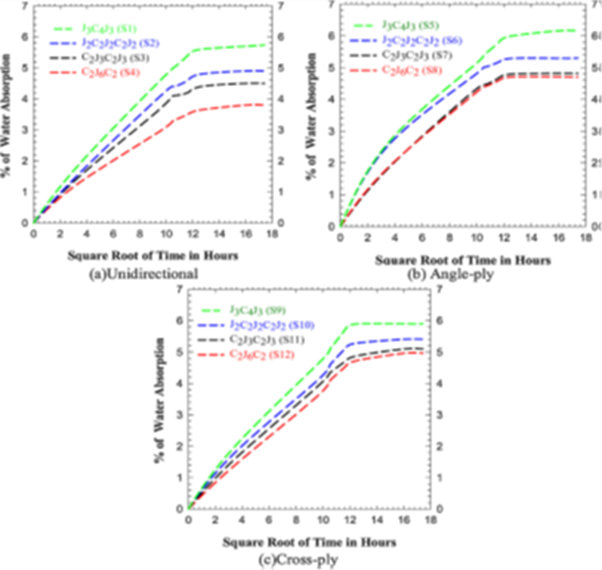

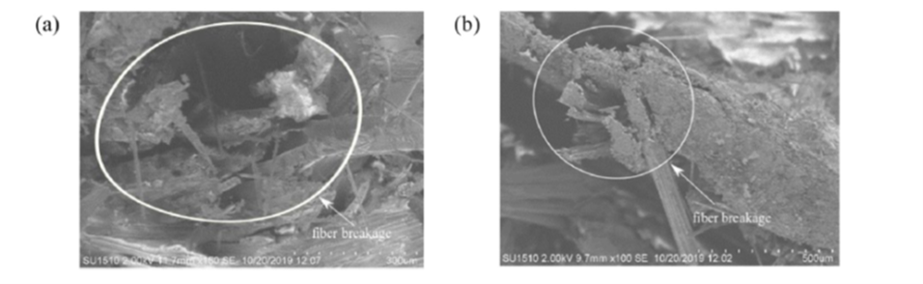

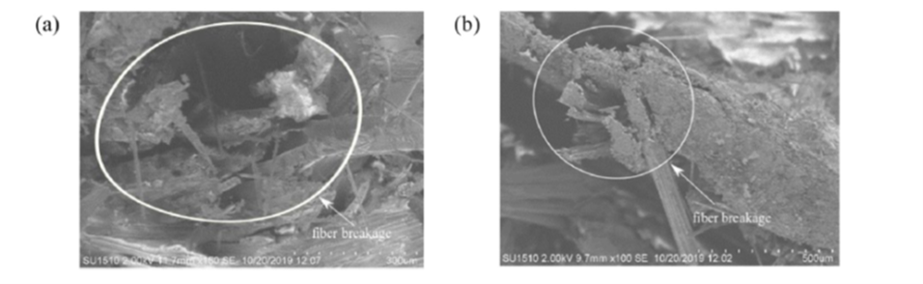

Experimental investigation of the mechanical and water absorption properties on fiber stacking sequence and orientation of jute/carbon epoxy hybrid composites

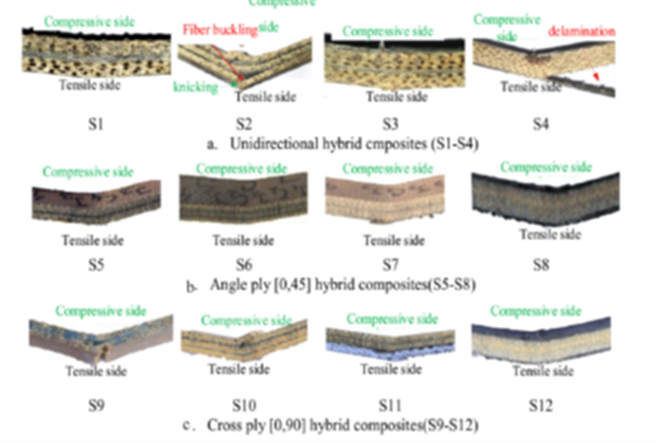

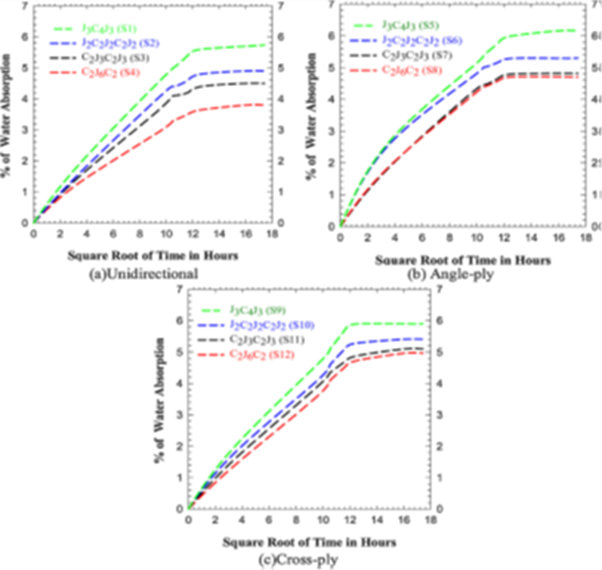

Combining natural and synthetic fibers can enhance performance and reduce hybrid composite costs. Composites with woven jute (six layers) and carbon fibers (four layers) were fabricated using vacuum-assisted resin infusion, with four stacking sequences and three fiber orientations. Tensile, flexural, impact, and water absorption tests showed that stacking sequence and fiber orientation significantly influence mechanical properties. The J3C4J3 sequence achieved the highest tensile strength (571 MPa), while C2J6C2 had the highest flexural strength (455 MPa), impact strength (30 kJ/m²), and lowest water absorption (3.8%). Unidirectional hybrids outperformed angle-ply and cross-ply configurations. These composites offer potential for lightweight, load-bearing structural applications

Fig 3: Fabrication and analysis of laminated jute and carbon fiber hybrid composites. Image taken from (Sujon et al., Journal of Material Research and Technology (JMR&T), 2020)

Fig 3: Fabrication and analysis of laminated jute and carbon fiber hybrid composites. Image taken from (Sujon et al., Journal of Material Research and Technology (JMR&T), 2020)

Densified wood composites

Principal investigator: Prof. Dr. Mohammad Ahsan Habib, Dr. Mohammad Nasim

Associate investigators: Dr. Abu Shaid Sujon; Md. Hasibur Rahman Hamim

Densified wood composite is an engineered material created by compressing natural wood fibers under high pressure, often combined with sustainable adhesives, to produce a product that boasts superior strength, durability, and resistance to environmental factors compared to conventional wood. The project on densified wood composites aims to develop these advanced materials in alignment with sustainable manufacturing practices. By exploring innovative densification techniques, the lab seeks to enhance the mechanical properties and dimensional stability of wood, transforming it into a viable, eco-friendly alternative to traditional construction materials.

Publications

•Hamim, H. R., Hasan, T., Shahriar, F., Chowdhury, S. R., Rahman, Md. A., Nasim, M., & Habib, M. A. (2025). Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence. In Composites Part C: Open Access (Vol. 16, p. 100564). Elsevier BV. https://doi.org/10.1016/j.jcomc.2025.100564

• Baigh, T. A., Nanzeeba, F., Hamim, H. R., & Habib, M. A. (2023). A comprehensive study on the effect of hybridization and stacking sequence in fabricating cotton-blended jute and pineapple leaf fibre biocomposites. Heliyon, 9(9). https://doi.org/10.1016/j.heliyon.2023.e19792

• Sujon, Md. A. S., Habib, M. A., & Abedin, M. Z. (2020). Experimental investigation of the mechanical and water absorption properties on fiber stacking sequence and orientation of jute/carbon epoxy hybrid composites. Journal of Materials Research and Technology, 9(5), 10970–10981. https://doi.org/10.1016/j.jmrt.2020.07.079

• Sujon, A. S., Mehfuz, N., & Habib, M. A. (2020). EXPERIMENTAL AND NUMERICAL INVESTIGATION ON THE TENSILE AND WATER ABSORPTION BEHAVIOR OF JUTE/CARBON REINFORCED EPOXY COMPOSITE. INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND TECHNOLOGY (IJMET), 11(2). https://doi.org/10.34218/IJMET.11.2.2020.012

• Sujon, A. S., Supto, T. H., Shariar, F., Pallab, M. M. R., Zoynal Abedin, M., & Ahsan Habib, M. (2020). Fabrication and Experimental Investigation on Tensile and Flexural Properties for Different Stacking Sequence of Jute and Carbon Fiber Reinforced Epoxy Composite. Key Engineering Materials, 858, 72–77. https://doi.org/10.4028/www.scientific.net/KEM.858.72

• Dr. Mohammad Ahsan Habib;

Professor & Head of the Department, Department of Mechanical and Production Engineering, Islamic University of Technology

Co-Investigator:

• Dr. Mohammad Nasim

Assistant Professor, Department of Mechanical and Production Engineering, Islamic University of Technology

•Dr. Abu Shaid Sujon

Assistant Professor, Department of Mechanical and Production Engineering, Islamic University of Technology

• Md. Hasibur Rahman Hamim

Junior Lecturer, Department of Mechanical and Production Engineering, Islamic University of Technology

Undergraduate researchers:

• Sazidur Rahman Chowdhury (ME’20)

• Ahsanul Amin (ME’20)

• Md Abraar Hossain (ME’20)

• Tasfia Binte Afsar(ME’20)

Research

The world is shifting from monolithic materials to composite materials due to its many useful properties. Composites are materials that are constructed from two or more materials. Our research group aims to develop and characterize composite materials for use in structural and functional applications by leveraging our expertise in mechanical engineering and material science.

Research themes

Sustainable fibers-reinforced composites

Principal investigator: Prof. Dr. Mohammad Ahsan Habib

Associate investigators: Dr. Abu Shaid Sujon; Md. Hasibur Rahman Hamim

Incorporating the diverse properties of cellulosic fibers, commonly known as natural fibers, to develop composite materials have been an active area of research for the past half – century. With the aim to produce sustainable materials for applications, we employ fabrication techniques such as vacuum resin-infusion, hand layup vacuum pressing to produce composite materials reinforced with untreated, or chemically modified, natural fibers . We also aim to provide an in-depth analysis of the mechanical behavior of the developed composite materials using state-of-the-art CO2 laser cutting techniques to develop the specimens, and characterization techniques such as tensile, flexural, impact, vibration and moisture absorption tests, along with Scanning Electron Microscopy (SEM) imaging. Our area of application for our developed composites includes, but not limited to, automotive, infrastructure and biomedical engineering. We are also investigating on the effect of nanofillers (such as graphene) on the mechanical and electrical properties of the sustainable composites.

Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence

Biocompatible basalt-silk fiber/PLA composites were developed using five stacking sequences and graphene nanoplatelet (GNP) reinforcement. The ALT configuration exhibited the best mechanical properties, with a tensile strength of 136.54 MPa and impact energy of 36.84 kJ/m². SEM analysis revealed delamination as the primary failure mode. The addition of 6 wt.% GNP enhanced damping but failed to achieve conductivity. These sustainable composites hold promise for multifunctional applications with reduced environmental impact.

Fig 1: Graphical abstract from “Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence” (Hamim HR et al, Composites Part C: Open Access, 2025)

Fig 1: Graphical abstract from “Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence” (Hamim HR et al, Composites Part C: Open Access, 2025)A comprehensive study on the effect of hybridization and stacking sequence in fabricating cotton-blended jute and pineapple leaf fibre biocomposites

Hybridizing biocomposites by combining discarded cotton-blended pineapple leaf fiber (PALF) and jute fiber fabrics enhances recyclability and sustainability. Four hybrid and two unhybridized composites were analyzed for mechanical, moisture absorption, and vibration properties. JFRP composites showed the highest tensile strength (35.16 MPa), while hybrid composites reached 32.16 MPa. The 4P5J-2 stacking sequence exhibited the highest tensile modulus (1.315 GPa), and a jute-dominant hybrid had the greatest elongation (15.94%). The 4P5J-1 hybrid achieved a flexural strength (44.36 MPa) comparable to JFRP (44.91 MPa) with a 78.57% flexural modulus increase over PFRP. Moisture absorption decreased with hybridization, and PALF plies on the outer layers improved damping. These findings highlight hybridization and stacking sequence as key factors in composite performance, promoting the use of textile waste for sustainable automotive applications.

Fig 2: Fabrication and analysis of cellulose fiber-based composites using vacuum bagging. Image taken from (Baigh & Nanzeeba et al, Heliyon, 2023)

Fig 2: Fabrication and analysis of cellulose fiber-based composites using vacuum bagging. Image taken from (Baigh & Nanzeeba et al, Heliyon, 2023)Experimental investigation of the mechanical and water absorption properties on fiber stacking sequence and orientation of jute/carbon epoxy hybrid composites

Combining natural and synthetic fibers can enhance performance and reduce hybrid composite costs. Composites with woven jute (six layers) and carbon fibers (four layers) were fabricated using vacuum-assisted resin infusion, with four stacking sequences and three fiber orientations. Tensile, flexural, impact, and water absorption tests showed that stacking sequence and fiber orientation significantly influence mechanical properties. The J3C4J3 sequence achieved the highest tensile strength (571 MPa), while C2J6C2 had the highest flexural strength (455 MPa), impact strength (30 kJ/m²), and lowest water absorption (3.8%). Unidirectional hybrids outperformed angle-ply and cross-ply configurations. These composites offer potential for lightweight, load-bearing structural applications

Fig 3: Fabrication and analysis of laminated jute and carbon fiber hybrid composites. Image taken from (Sujon et al., Journal of Material Research and Technology (JMR&T), 2020)

Fig 3: Fabrication and analysis of laminated jute and carbon fiber hybrid composites. Image taken from (Sujon et al., Journal of Material Research and Technology (JMR&T), 2020)

Densified wood composites

Principal investigator: Prof. Dr. Mohammad Ahsan Habib, Dr. Mohammad Nasim

Associate investigators: Dr. Abu Shaid Sujon; Md. Hasibur Rahman Hamim

Densified wood composite is an engineered material created by compressing natural wood fibers under high pressure, often combined with sustainable adhesives, to produce a product that boasts superior strength, durability, and resistance to environmental factors compared to conventional wood. The project on densified wood composites aims to develop these advanced materials in alignment with sustainable manufacturing practices. By exploring innovative densification techniques, the lab seeks to enhance the mechanical properties and dimensional stability of wood, transforming it into a viable, eco-friendly alternative to traditional construction materials.

Publications

•Hamim, H. R., Hasan, T., Shahriar, F., Chowdhury, S. R., Rahman, Md. A., Nasim, M., & Habib, M. A. (2025). Basalt-silk fiber reinforced PLA composites: Effect of graphene fillers and stacking sequence. In Composites Part C: Open Access (Vol. 16, p. 100564). Elsevier BV. https://doi.org/10.1016/j.jcomc.2025.100564

• Baigh, T. A., Nanzeeba, F., Hamim, H. R., & Habib, M. A. (2023). A comprehensive study on the effect of hybridization and stacking sequence in fabricating cotton-blended jute and pineapple leaf fibre biocomposites. Heliyon, 9(9). https://doi.org/10.1016/j.heliyon.2023.e19792

• Sujon, Md. A. S., Habib, M. A., & Abedin, M. Z. (2020). Experimental investigation of the mechanical and water absorption properties on fiber stacking sequence and orientation of jute/carbon epoxy hybrid composites. Journal of Materials Research and Technology, 9(5), 10970–10981. https://doi.org/10.1016/j.jmrt.2020.07.079

• Sujon, A. S., Mehfuz, N., & Habib, M. A. (2020). EXPERIMENTAL AND NUMERICAL INVESTIGATION ON THE TENSILE AND WATER ABSORPTION BEHAVIOR OF JUTE/CARBON REINFORCED EPOXY COMPOSITE. INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND TECHNOLOGY (IJMET), 11(2). https://doi.org/10.34218/IJMET.11.2.2020.012

• Sujon, A. S., Supto, T. H., Shariar, F., Pallab, M. M. R., Zoynal Abedin, M., & Ahsan Habib, M. (2020). Fabrication and Experimental Investigation on Tensile and Flexural Properties for Different Stacking Sequence of Jute and Carbon Fiber Reinforced Epoxy Composite. Key Engineering Materials, 858, 72–77. https://doi.org/10.4028/www.scientific.net/KEM.858.72